For service life, the Company has accumulated years of experience in the design of products of this kind, avoiding potential failure modes, solving the problem of corrosion in metal plate coating, living up to good performance and long service life. The cost control for fuel cell products is associated with product development capabilities. Stronger product development capability means higher product power density and fewer materials and single cells consumed for the same kilowatt, thus more cost will be saved. With more than 20 years of product development experience, the core technical team of Jichong Hydrogen has accumulated a wealth of design experience, test data, research methods, etc., forming a unique technology development process, and accordingly knowing how to achieve the optimum between performance and cost

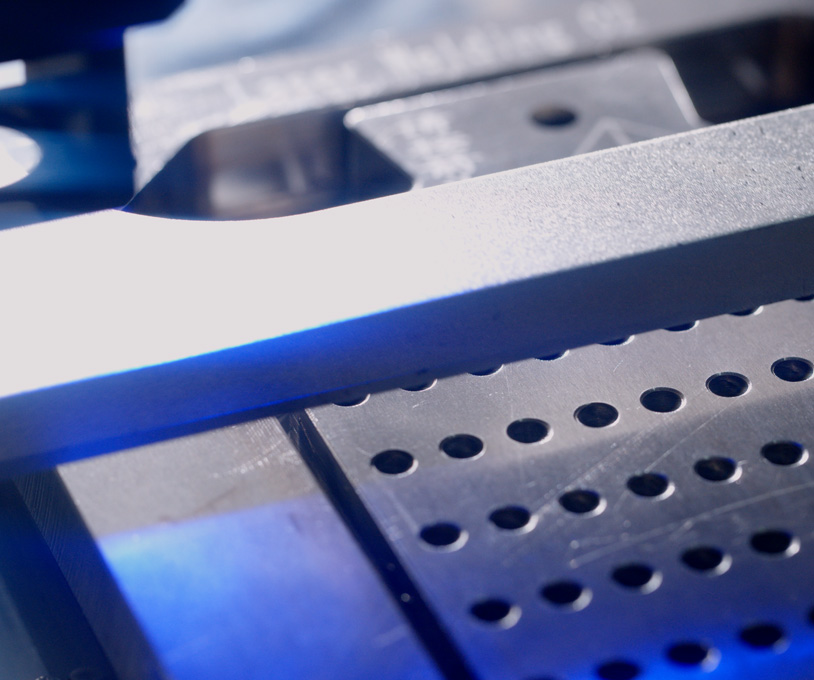

The fuel cell stack is composed of single cells, and the cost of single cells mainly consists of material cost and manufacturing cost. Herein, the cost of membrane electrodes accounts for the majority of the material cost, and the entire industry is basically at the same level, with the difference arising from bipolar plate, while the material cost of bipolar plate mainly lies in the coating. For the coating of Jichong Hydrogen, the unique fourth-generation super-corrosion-resistant conductive non-precious metal bipolar plate coating from Changzhou EMT is adopted, which greatly brings down the cost of bipolar plate and thus achieves relatively low cost per single cell.

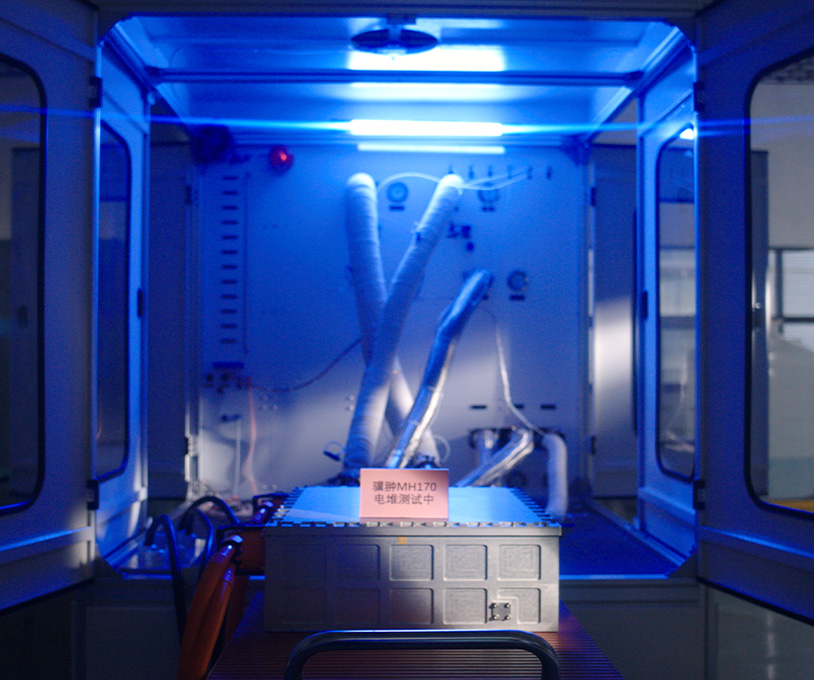

Regarding manufacturing cost, from metal bipolar plate manufacturing to stack assembling, all of the core businesses under Jizhong Hydrogen are independently developed and manufactured by Shenzhen Zhongwei, which is wholly owned by the Company. From the perspective of equipment amortization, Jizhong Hydrogen has independent control over manufacturing cost and accordingly has inborn advantages. Located in Zhangjiagang, Jiangsu Jichong, with designed annual capacity of 200MW, is the first pilot test base invested and built by Jichong Hydrogen. So far, the production line has been subjected to automatic upgrading of the whole process, making it the most complete domestic production line with the largest production capacity and the most mature technology for metal bipolar plate and stack. Aside from the Jiangsu Jichong Pilot Test Base, the second-generation fully-automatic and intelligent production lines of Jichong Hydrogen have been successfully deployed in Xinxiang, Luoyang and other places, with a designed annual capacity of 500MW for each.